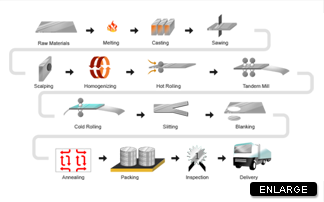

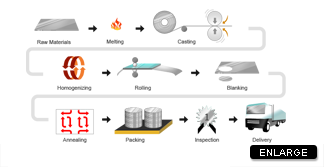

At Meyer, we always put quality first. In order to achieve this objective, Meyer's management has invested in the most technologically advanced machinery and equipment. Our melting facilities make use of state of the art technology to ensure high production efficiency while being environmentally friendly. We have a total of 5 melting furnaces, each of which holds 20 MT of molten aluminium. Our Hong Kong operation has adopted the vertical direct chilled (VDC) caster which produces 4 MT each slab. In Thailand, we use the continuous casting technology. We can cast strip with a thickness range between 3mm and 10mm and a width up to 1,600mm. Our continuous casters are installed with the profile measurement device to achieve the desirable profile. |

We established our own Material Flow System (MFS) to ensure good product traceability. Rolling recipes that fulfill the customers' requirements are shown to the operator in the rolling process. Closed loop control in the process is vital to ensure quality consistency. Computer Integrated Manufacturing (CIM) is our ultimate goal. Meyer's total cold rolling capacity is 140,000 MT per year. The rolling thickness ranges from 0.6mm to 7mm with a coil width up to 1,525mm. The maximum coil size is 7 MT. |

|||||

We know our customers have high expectations of our product's surface quality. Therefore, we have made a substantial investment to develop scratch free product and excellent flatness control. We have a highly automatic batch annealing furnaces, blanking lines, cut to length lines and packing lines in our finishing section. With all these investments in the hands of our dedicated working staff, we are confident to provide product that meets our customers' quality requirements and exceeds their expectations. |

Throughout the entire manufacturing process of our circles, sheet and coils, we maintain rigorous quality assurance monitoring and testing procedures. Mechanical and chemical compositions of our products are closely monitored to achieve total customer satisfaction. We use the AA (Aluminium Association) standard as our reference but generally control our product to tighter internal standards. Both of our rolling mills are ISO9001 certified. With the help of the ISO Quality Management System, we continually improve our company's performance and have established a highly reliable and stable process. |

|

||||

As one of Asia's leading aluminum rolling mills, our investment is not solely in technology, but in people as well – their health, safety and welfare. Consistently high quality, high volume output and a "right first time" customer oriented service policy are only achieved through the perfect blend of men and machine. Whilst essential environmental issues confront industries today, the recyclable quality of aluminium is increasingly recognized. As a socially aware and responsible company, we have gone to great lengths to implement many of the best environmental practices in our business. |

Few materials are quite as versatile as aluminium and Meyer's rolled semis play their part in a wide variety of everyday uses, as well as in new and innovative applications, that are as varied and diverse as our worldwide customer base. One thing is certain. Given our successful track record, sound financial base and progressive outlook, we are as committed as ever to investing today to ensure that we will continue to meet our customers' needs for tomorrow. |

| © 2011 Meyer Aluminium Limited. |